OFFERING THE LOWEST PRICES AVAILABLE

COMPACTION & BALING SOLUTIONS

VERTICAL COMPACTORS

VERTICAL BALERS

LARGE COMPACTORS

HORIZONTAL BALERS

DRUM CRUSHERS

AEROSOL CAN CRUSHERS

RECYCLING SOLUTIONS

CAN CRUSHERS

GLASS CRUSHERS

GLASS PULVERIZERS

LIQUID EXTRACTION/CAN & PET EXTRACTORS

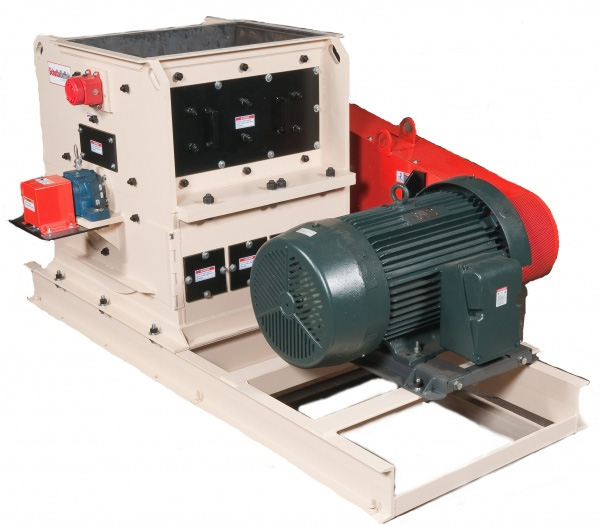

AGGREGATE MATERIAL CRUSHERS

HAMMER MILLS

At Compactors Inc., we provide a complete line of commercial trash compactor and waste management solutions. Our vertical compactors, chute fed compactors, densifiers, can crushers, glass crushers, balers and shredders will help reduce waste hauling costs, reduce manpower, make your company environmentally responsible and will provide you with a rapid return on your investment. If your company already has a waste reduction solution, we offer a full line of compactor bags, lifts, parts and accessories for any compactor or volume reduction equipment you may have at extremely competitive prices.

To help your company achieve a significant volume reduction of recyclables and waste products, please contact us for a free quote.

Here are the pictures of our application using your compactor. We went from paying $18-20,000 a year for plastic removal by a local waste company to selling our compacted bales to our pots and tray manufacturers for $8-10,000 per year!!! So…… we paid for our compactor in less than a year!!! Every time the compactor runs it sounds just like printing money. Thanks for delivering a great product and one that does exactly what you said it would! Very refreshing to deal with an honorable company.”

John Hardiman

American Farms

“You and Lisa have made this process, from start to finish, an absolute pleasure Sayra. Keep up the great customer service. We appreciate what you do!! Thanks for your help and we are absolutely LOVING our new compactor!!!”

Cathy Ring

End Hunger Calvert

“Our disposal costs have dropped which at least covers the cost of the compactors. Aside from the monetary aspect, the compactors allow the stores to be considerably cleaner.Clean-up at night is much easier because we have no trash cluttering up the back room of the store. All in all, we are very pleased with the compactors.”

Doug Gehrig

McDonalds

“We would like to thank the great service of Compactors Inc. We currently have on board the Vertical Trash Compactor model 4500SS. It has been a tremendous help with the recycling of our trash. The machine works great and is very friendly to use. We have been using this equipment for about four of five years now. When we need parts due to this machine being used over 30 times on a daily basis, Compactors Inc. is there for logistic support and they even give credit back for certain parts. My experience working with Compactors Inc. is a very reliable company to do business with. So thank you again for the great service from the USNS Laramie (T-AO 203) crew!”

Teo Truzy

Department of the Navy