HAMMER MILLS

Schutte Hammermill products are known worldwide for their rugged construction, economical price, day-in-day-out dependability and a line of the highest quality, on-demand replacement wear parts. Our products are made in the USA, proudly manufactured in our facility in Buffalo, New York.

Compactors, Inc. provides exceptional customer service and integrated turn-key solutions. Let us provide an estimate for you to include: Equipment, Options, Freight, Installation, Commissioning/Training and On-Site Engineering Support.

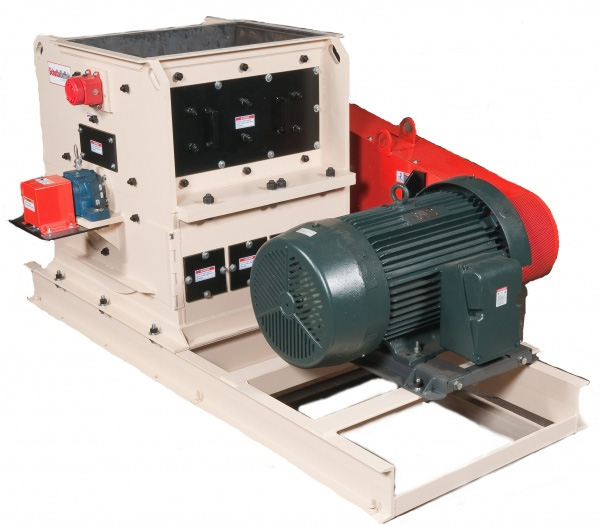

HAMMER MILLS – WA SERIES

The WA Series is a gravity discharge hammer mill that can be constructed with a wide variety of grinding rotors and screen configurations to guarantee unmatched performance. Available in more than 20 sizes, ranging from 6” to 72”, each mill features replaceable wear plates to protect the mill housing from wear that may result from processing abrasive materials. All models of the WA Series are custom configured to suit the user’s material and production goals. In-feed and discharge chutes are designed to accommodate any method of feeding and takeaway, ensuring a clean and safe operating environment.

The WA Series is a gravity discharge hammer mill that can be constructed with a wide variety of grinding rotors and screen configurations to guarantee unmatched performance. Available in more than 20 sizes, ranging from 6” to 72”, each mill features replaceable wear plates to protect the mill housing from wear that may result from processing abrasive materials. All models of the WA Series are custom configured to suit the user’s material and production goals. In-feed and discharge chutes are designed to accommodate any method of feeding and takeaway, ensuring a clean and safe operating environment.

HAMMER MILLS – BD SERIES

High capacity, single rotor, hammer and comb design. Ideal for most de-agglomeration applications. Ranging in sizes from laboratory scale to heavy duty industrial, the BD Series Lump Breaker is available in carbon or stainless steel with a hammer and comb design tailored to individual applications. Various rotor speeds are available to optimize performance on a variety of materials reducing dry and/or or hardened agglomerates to a flowable end product.

DETAILS FREE QUOTEHAMMER MILLS – 44 SERIES

Low speed (1800 RPM), high production. Nearly full screen coverage of 44″ diameter rotor. The 44 Series Circ-U-Flow hammer mill is designed for very high production grinding of agricultural products, feed and grain, light wood waste and other relatively easy to grind materials. The nearly full circle screen translates to a larger open screen area and thus the highest possible production rates on materials that do not require initial grinding against a breaker plate. Suitable for either gravity or pneumatic evacuation.

DETAILS FREE QUOTEHAMMER MILLS – RC SERIES

The RC Series Industrial Crusher is ideal for processing a variety of large, heavy or bulky but friable materials. The large throat allows for easy in-feed of blocky materials. High tonnage rates are achieved with the lowest possible amount of wear and tear. The versatile RC Series can process a variety of recycled materials such as waste glass, steel and non-ferrous slags, and mineral processing waste, just to name a few.

DETAILS FREE QUOTE