VERTICAL BALERS

MODEL X50 HD

Features

- Most material types are compacted easily

- Impressive compression ratio

- Press force 110,000 lbs

- Very little expansion of material between press cycles

- Tie off finished bales with either steel wire or plastic strapping

- Fast press cycle (28 secs)

- Electrical control panel safe and easy to access

- All moving parts located inside machine

Optional

- Tie your bales with strapping or steel wires – We offer strapping and steel wires for your balers. Contact us and let us guide you to the right choice for your machine and waste material.

- Flap door for baler lets you handle bottles and cans easily – Avoid waste back-run when the door is opened. A flap door works like a chute and is suitable for cans and PET bottles.

- Make your baler resistant against liquids – Prolong machine surface life with a galvanization. Suitable for applications in severe or wet environments or for handling waste with residual liquids.

How does the baler work?

Time saving and easy waste handling

- Fill your plastic or cardboard waste into the baler

- A full-light indicator tells you when the chamber is full

- Tie off and eject the finished bale

- Remove the bale and store until collection

Learn more about the information we require to provide you with a quote for a vertical baler.

SAFE AND EASY TO OPERATE

Our equipment has the highest level of safety. Don’t settle with less!

PRODUCT SPECIFICATIONS

| Bale Size: 48″ W x 30″ D x 48″ H | Bale Weight Cardboard: 750-1,000 lbs |

| Press Force: 110,000 lbs | Motor: 7.5 HP |

| Noise Level: 62-64 dB | Cycle Time Average: 18 seconds |

| Dimensions: 78″ W x 56″ D x 100″ H | Full Bale Light: Yes |

| Stroke: 48″ | Machine Weight: 5,370 lbs |

PRODUCT VIDEO

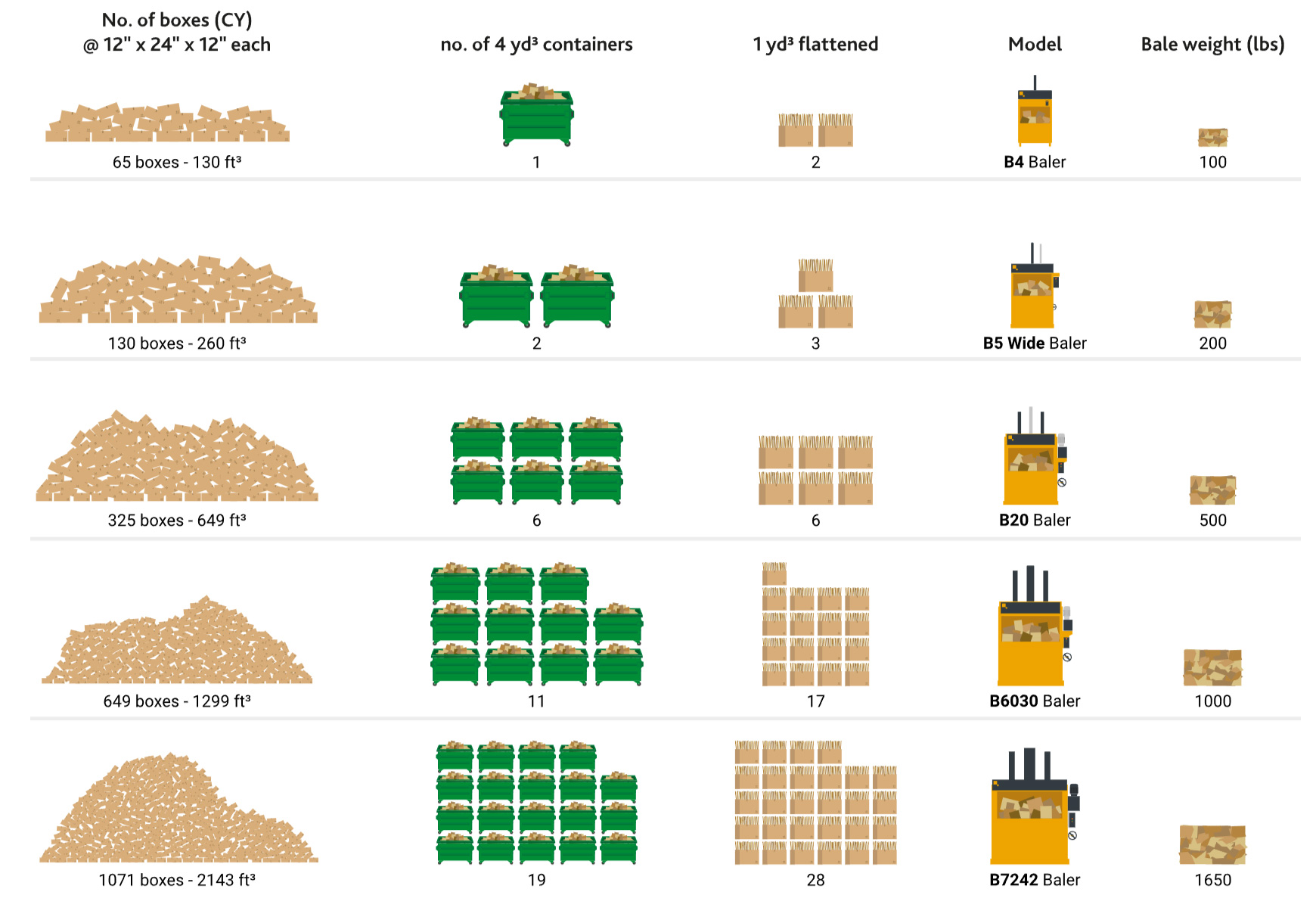

BALER COMPRESSION OF CARDBOARD

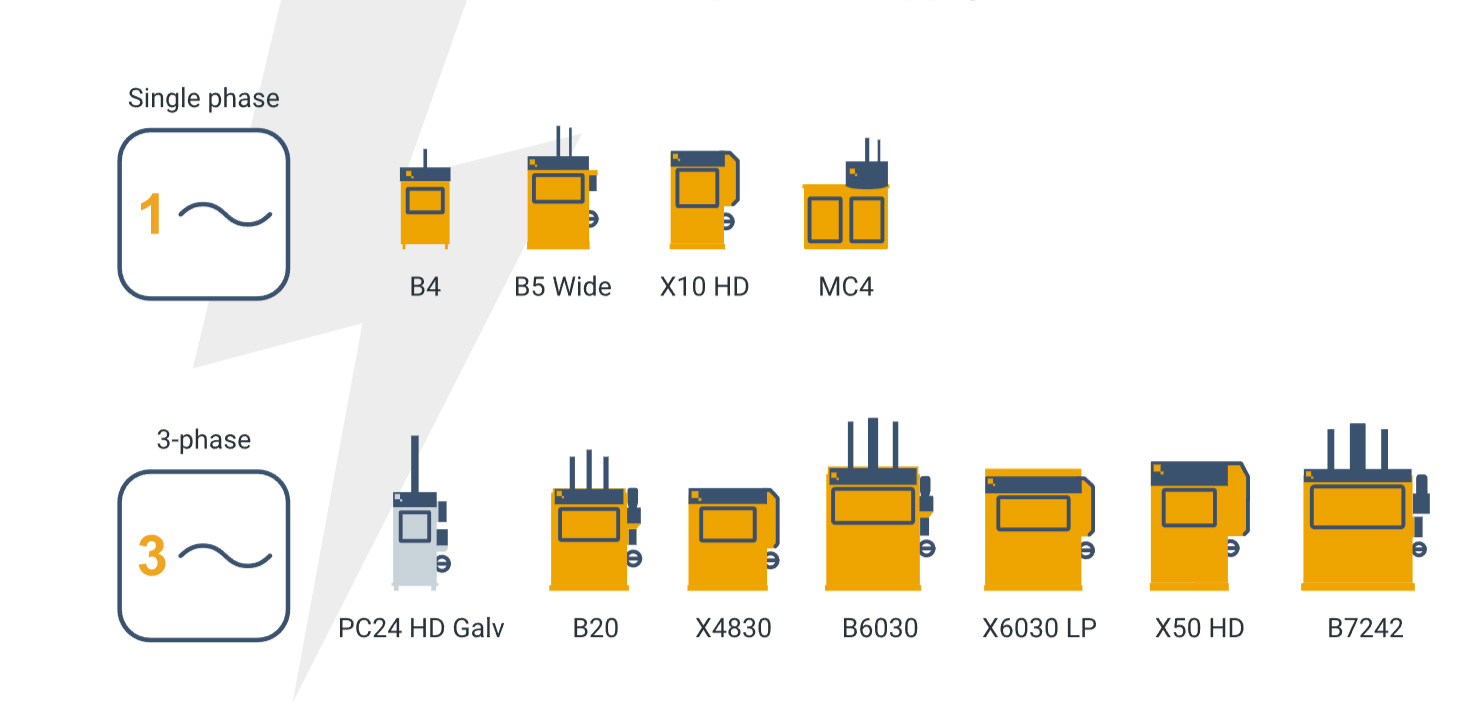

BALER POWER SUPPLY

PRODUCT GALLERY