COMMERCIAL CAN DENSIFIERS

Our can densifiers are ideal for a variety of industries, including recycling centers, manufacturing plants, hospitality, and commercial facilities that generate large volumes of can waste. By incorporating our densifiers into your operations, you can improve operational efficiency, reduce waste handling costs, and contribute to environmental sustainability. Features such as user-friendly controls, durable construction, and high compaction ratios make our can densifiers a valuable asset for any business committed to effective waste management. Trust Compactors Inc. to provide the best can densifiers tailored to your specific needs, ensuring efficient and sustainable recycling solutions for your organization.

CAN DENSIFIER – MODEL 10P

“The Solution for Low Volume Can Recycling – Shipboard Marine Industries and Recycling Centers”

The Model 10P Densifier is designed for applications where a high density slug of beverage cans or metal cans is required but where space is limited. Operation is fully automatic. The unit is activated by an electric eye which senses material in the loading hopper. The machine also senses when there is a complete slug and signals for the operator to unload the machine. Our can densifiers can also be used as filter presses and for dewatering applications. Throughputs of up to 85 lbs per hour.

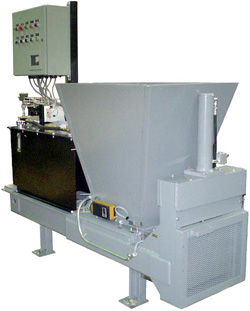

CAN DENSIFIER – SERIES 20P, 40P & 80P

“Our Most Popular Can Densifier Available in 5 Different Configurations – Recycling Centers – Can Redemption Facilities, US and Foreign Militaries, Municipalities, Cruise Lines, Offshore Shopping Industry, Food Processing Facilities, Canning Operations, Meat Packing Facilities and Auto Industries”

Our Can Densifiers are designed to produce a single slug of densified material. Our densifiers will process aluminum, steel or tin cans and oil filters. Our densifiers are also used in de-watering applications for drink containers, juice boxes, tetra paks, drink pouches, plastic bottles, meat by products and a multitude of other products. Custom configurations are our specialty. Conveyors available.