FULL BEVERAGE AND FULL CONTAINER DESTRUCTION

Our full beverage destruction machines are ideal for various industries, including beverage manufacturing, distribution, retail, and hospitality. By integrating these machines into your waste management process, you can enhance operational efficiency, ensure compliance with environmental regulations, and contribute to sustainable practices. The ability to securely destroy and recycle full beverage containers not only safeguards your brand but also supports environmental sustainability by promoting the recycling of materials. Trust Compactors Inc. to provide the best full beverage destruction machines tailored to your specific needs, ensuring efficient, secure, and eco-friendly waste management for your business.

LIQUID EXTRACTION BALER – MODEL V3016HD (30″)

“The Ideal Solution for Beverage Distributors. Bale Weights Up To 250 Pounds.”

The Model V3016HD Liquid Extraction Baler drains and bales refuse beverage and liquid containers in one step. An internal system captures the liquid waste and diverts it to an approved drain. This makes it possible to bale refuse containers seven times faster than when liquids are extracted manually. A single bale can be made from up to 4,000 aluminum beverage cans and up to 2,000 plastic beverage bottles.

MODEL 20P

“Our Most Popular Can Densifier Available in 5 Different Configurations – Recycling Centers – Can Redemption Facilities, Foam Recyclers and Polystyrene Manufacturers and Many More”

Our Can Densifiers are designed to produce a single slug of densified material. Our densifiers will process aluminum, steel or tin cans and oil filters. Our densifiers are also used in de-watering applications for drink containers, juice boxes, tetra paks, drink pouches, plastic bottles, meat by products and a multitude of other products. Custom configurations are our specialty. Conveyors available.

LIQUID CONTAINER DESTRUCTION – XTRACTOR

The Xtractor is much more than a simple can crusher. The Xtractor is a specialized piece of equipment based on the Patented High Density Extruder that is specifically designed for removing liquids from aluminum cans, plastic bottles and other liquid containers. It makes no difference if the package is aseptic, plastic or aluminum the Xtractor can do the job.

TOTAL PRODUCT DESTRUCTION – XCYCLER

Finally, a machine that can do it all. The XCycler is the answer for processing large volumes of full plastic or aluminum liquid containers. It dumps, perforates, dewaters, crushes, and bales in one compact and integrated system. Large milled sized bales, high thru-put and corrosion resistant stainless steel construction make this equipment a winner!

HIGH DENSITY EXTRUDER – MODEL 2013X-V3

Sebright Products/Bright Technologies High Density Extruders were originally designed in 1992 to dewater wet rejects from the pulp and paper industry where they routinely run around the clock unattended. This demanding application requires the equipment to accept a wide variety of materials and be durable and low maintenance. The High Density Extruder was first customized for coolant recovery on grinding swarf applications in 1996 for the auto industry. A wide range of metal grinding applications have benefited from this unique and robust equipment solution.

HIGH DENSITY EXTRUDER – MODELS 3024XS-6260XS

The High Density Extruders are used to extract liquids from many types of industrial refuse byproducts, or to remove liquids from many commonly used packaged products and beverages. Tested and proven time and time again, the High Density Extruder is the best performing, most efficient and most reliable ram press available today.

REM® MODEL CC5B Series

Process “line rejects” or “out dated product” and recover aluminum cans and PET Containers for recycling with the Series 5B Crushing System. Our Model CC-5B crushes aluminum cans while the CC-5B Perf also crushes PET Bottles. Both come complete with an in-feed conveyor, totally enclosed crushing mechanism, capture tank with drain, and an out-feed conveyor with fresh water rinse.

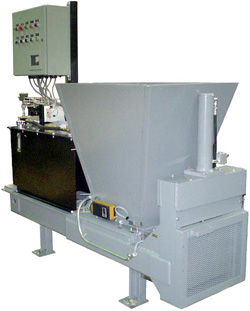

REM® Dewatering Auger Compactor

With over 40 years of experience in the recycling equipment business and many years of re-search, we have developed the Dewatering Auger Compactor for aluminum cans, plastic bottles, aseptic and tetra pack.

REM® GLASS BREAKERS – GB SERIES

The GB Series Glass Breakers are complete crushing systems. Rugged, unitized construction produces a machine that will withstand years of punishing use in recycling operations. The GB series requires minimal maintenance and has a reputation in the recycling industry as a crusher built to last.

REM® MODEL GB/BC

Process “line-rejects” or “out-dated product” and recover recyclable glass with the GB/BC Full Beverage Glass Breaker. To operate, simply load the glass containers into the Glass Breaker hopper. The rotating steel crushing drum and breaker plate design produces a uniform cullet size acceptable to the recycling industry. The broken glass is discharged into a screening chamber where the liquid is separated into a capture tank with drain.

REM® MODEL MV PERF

Process full beverage “line rejects” or “out dated product” and recover aluminum cans and PET Containers for recycling on an extreme scale with the Series MV Perf Crushing System. Our Model MV-PERF processes both PET containers as well as aluminum cans.

REM® MODEL HV PERF

With a processing capacity of up to 20,000 containers per hour, the Model HV Perf Compactor is the full beverage destruction equipment you’ve been waiting for. Designed to fill the need for a very high volume full beverage destruction system with the added benefit of absolutely no handling of the destroyed product by your in-plant labor.