SEARCH BY MATERIAL – ALUMINUM AND STEEL CANS

To help you save space, time, and environment, and achieve a significant volume reduction of recyclables and waste products, please contact us at 1.800.423.4003 or fill out our online form for a free quote.

CAN DENSIFIER – MODEL 10P

“The Solution for Low Volume Can Recycling – Shipboard Marine Industries and Recycling Centers”

The Model 10P Densifier is designed for applications where a high density slug of beverage cans or metal cans is required but where space is limited. Operation is fully automatic. The unit is activated by an electric eye which senses material in the loading hopper. The machine also senses when there is a complete slug and signals for the operator to unload the machine. Our can densifiers can also be used as filter presses and for dewatering applications. Throughputs of up to 85 lbs per hour.

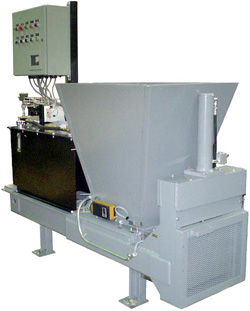

CAN DENSIFIER – MODEL 20P

“Our Most Popular Can Densifier Available in 5 Different Configurations – Recycling Centers – Can Redemption Facilities, Foam Recyclers and Polystyrene Manufacturers and Many More”

Our Can Densifiers are designed to produce a single slug of densified material. Our densifiers will process aluminum, steel or tin cans and oil filters. Our densifiers are also used in de-watering applications for drink containers, juice boxes, tetra paks, drink pouches, plastic bottles, meat by products and a multitude of other products. Custom configurations are our specialty. Conveyors available.

CAN CRUSHER – PRC SERIES

The PRC Series Can Crushers are complete separating and crushing units for aluminum cans. The design of this unit has the reputation for dependability and low maintenance. Rugged steel construction makes the PRC Series the one to use for long-term productivity.

CAN CRUSHERS – MODEL CC5B Series

Process “line rejects” or “out-dated product” and recover aluminum cans and P.E.T. containers for recycling with the 5B Series Crushing System. Our CC 5B crushes aluminum cans while our CC 5B PERF processes both P.E.T. containers and aluminum cans.

CAN CRUSHERS – MODEL MV PERF

Process full beverage “line rejects” or “out dated product” and recover aluminum cans and PET Containers for recycling on an extreme scale with the Series MV Perf Crushing System. Our Model MV-PERF processes both PET containers as well as aluminum cans.

CAN CRUSHERS – MODEL HV PERF

With a processing capacity of up to 20,000 containers per hour, the Model HV Perf Compactor is the full beverage destruction equipment you’ve been waiting for. Designed to fill the need for a very high volume full beverage destruction system with the added benefit of absolutely no handling of the destroyed product by your in-plant labor.

MASTER CAN BUYER – MODEL MCB-15

The Master Can Buyer Model MCB-15 makes aluminum can-buying fast and efficient, streamlines your customer service and simply makes your operation more efficient and profitable.

HIGH VOLUME CAN BUYER

The High Volume can buyer system for aluminum cans is the cleanest and most efficient can buying system on the market today. Multiple bags of Aluminum cans are loaded into the horizontal conveyor hopper by the operator or customer.

CAN FLATTENER BLOWER SERIES

The Can Flattener Blower Series are complete separating, crushing and blowing units for aluminum cans. The design of these units have the reputation for dependability and low maintenance.

CAN FLATTENER BLOWER – MODEL CC-10 EXT

We proudly introduce our first in a line of third generation can crushers destined to become the product of choice… the CC-10 EXT Can Flattener Blower for aluminum cans. The EXT is a complete separator, crusher, and blower unit capable of processing up to 3,500 pounds of cans per hour!