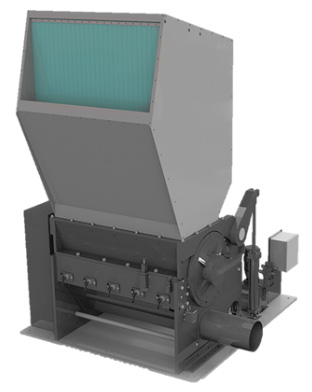

GRANULATORS

X SERIES

Reduced Energy Consumption

- Made possible by the TwinShear™ “scissor cutting” action rotor design

- Uses lower energy consumption without sacrificing throughput performance

Easy Accessibility & Cleanout

- Due to split chamber design, which raises the upper half of the cutting chamber, and lowers the screen cradle and discharge assembly via hydraulic cylinders

- Simplifies access for knife adjustments

- Air evacuation piping system does not need to be disconnected

Application Flexibility

- Configurations are available for many types of applications and client specific requirements

- Multiple options available for: Infeeds, rotors, cutting chambers, and evacuation systems

- Injection molded, blow molded, or extruded scrap

- Furniture and appliances

- Film and sheet

- Automotive moldings, ducts, furniture/appliance parts

Optional Features

- Multiple hopper designs

- Replaceable rotor knife seats

- Abrasion resistance package for high wear applications

- Water cooled rotor and chamber

- Digital load meter

PRODUCT SPECIFICATIONS

| Weight: 10,000-22,000 pounds | Motor: 50-150 HP |

| Throughput (est): 1,800-4,500 lbs/hr | Infeed Height: 103.5″ |