STATIONARY COMPACTORS

BACE SERIES

FEATURES

All welds meet AWS certification

All welds meet AWS certification- UL listed components

- 100% ETL & CETL approved

- Fully jig & fixtured heavy duty structural steel design

- 3-D SolidWorks Finite Element Analysis (FEA) stress analysis engineered units

- Factory tested & inspected (Quality Assurance Mgr.)

- High force HD model stationary compactor

- Energy efficient kilowatt reduction

- Highest platen forces

- Easy clean out removable covers

- Nema4 controls

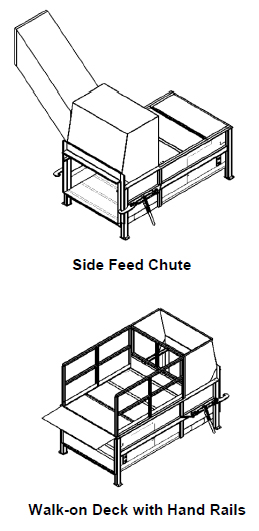

- Rear or side feed chute installations

- Doghouse & chutes constructed by BACE

- Heavy duty load binders

- Submersible power units

- Eliminates need for an oil heater

HOPPER OPTIONS

Walk on deck (700 lbs.) w/rails, 3-sided hopper, safety gate & interlock

Walk on deck (700 lbs.) w/rails, 3-sided hopper, safety gate & interlock- Drive on deck (8,000 lbs.) w/rails, 3-sided hopper, safety gate & interlock

- Full enclosure – walk on w/hopper, gate & switch 5 x 8

- Full enclosure – drive on w/hopper, gate & switch 5 x 8

- Dock feed doghouse w/2 plastic cellar doors & switches

- Dock feed top lid w/air shocks rear feed to back of compactor

- Full enclosure – walk on w/hopper, gate & switch 8′ x 10′

- Top feed hopper with hinged lid

- 3-sided “Side Feed” hopper

- Security door assembled with inside & outside frames

- Doghouse w/1 side door (LH or RH) with interlock

- Doghouse w/rear doors & interlock switch

- Through the wall – (side feed chute material, 4-sided blank doghouse for chute, rear feed chute material, security door assembled with inside & outside frames, thru the wall kit, extra side feed door with switch)