The Best Glass Crushers for Your Business

Glass crushers are used to crush or pulverize glass waste. Handling glass waste comes with different safety risks. The best way of managing glass waste is to convert it into small pieces called cullet or sand with the help of a glass crusher or pulverizer. Crushed or pulverized glass can be deposited into self-dumping hoppers, gaylords, super sacks, or open top roll off which makes handling and shipping easier and more economical. If your commercial activities are responsible for the production of glass waste or you have a waste recycling plant, then utilizing a glass crusher or pulverizer to reduce volume for handling and shipping is a must.

Glass crushers are used to crush or pulverize glass waste. Handling glass waste comes with different safety risks. The best way of managing glass waste is to convert it into small pieces called cullet or sand with the help of a glass crusher or pulverizer. Crushed or pulverized glass can be deposited into self-dumping hoppers, gaylords, super sacks, or open top roll off which makes handling and shipping easier and more economical. If your commercial activities are responsible for the production of glass waste or you have a waste recycling plant, then utilizing a glass crusher or pulverizer to reduce volume for handling and shipping is a must.

Why Glass Crushers?

The installation of a glass crusher is not just because of local laws or safety risks. The main reason is that glass waste is non-degradable. It does not decompose with time. There is only one solution for glass waste management and that is recycling.

The installation of a glass bottle crusher or a commercial glass crusher shows your commitment towards the protection of the environment. It affects your business reputation positively and helps your business to grow.

When to choose a Glass Crusher vs a Glass Pulverizer?

Choose a glass crusher for product destruction of defective or out of date products or when you need size reduction for storage and shipping. Glass crushers produce variable glass cullet approximately ¾” with sharp edges. This cullet is used for recycling purposes and can be used to make new glass products, fiber glass and aggregate.

Choose a glass crusher for product destruction of defective or out of date products or when you need size reduction for storage and shipping. Glass crushers produce variable glass cullet approximately ¾” with sharp edges. This cullet is used for recycling purposes and can be used to make new glass products, fiber glass and aggregate.

Choose a glass pulverizer when you intend to reuse or recycle the pulverized glass / sand into cement, aggregate or landscaping. Glass pulverizers converts glass to sand with no sharp edges, ranging from 3/8” minus to 1/8” minus.

Compactors Inc. Provides Complete Solutions for Glass Waste Management and Recycling

We provide many solutions to manage your glass waste and glass recycling programs. Our company has a wide range of different glass crushers and pulverizers which includes hand fed crushers, conveyor fed crushers and crushers that can be bulk fed. Below we have shortlisted the best glass crushers and pulverizers on the market.

With steel construction and easy operating procedure, this glass crusher machine is one of our most popular products. This crusher is mainly suitable for bottlers / brewers, bottling facilities, breweries, small businesses and municipalities because of its large capacity throughput and small footprint. The glass crusher comes with a liquid capture tank and drain. The model GB/BC also has a screening chamber. This glass crusher discharges glass cullet directly into a container for recycling thereby avoiding any manual handling.

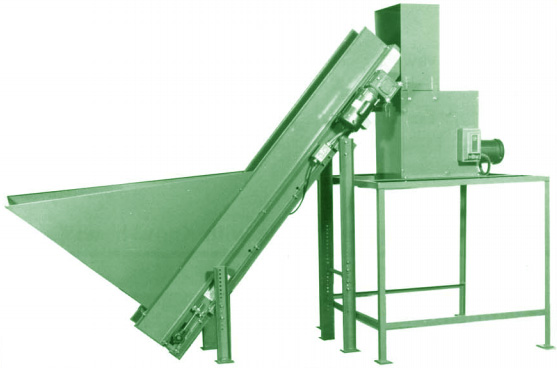

The GB series glass crusher is a highly efficient machine incorporating many standard features that are only options for other manufacturers. This crusher is suitable for bottlers / brewers, bottling facilities, breweries, glass recycling programs, small businesses and municipalities because of its large capacity throughput and small footprint. To operate, simply load the glass containers into the low in-feed hopper and the conveyor automatically feeds the crusher. The rotating steel crushing drum and breaker-plate design produces a uniform cullet size acceptable to the recycling industry. Features such as the self-cleaning tail pulley and enclosed conveyor belt make the GB a durable and low maintenance machine.

Choose a model with capacity up to 12,000 pounds per hour and the GB series will help you maximize shipping weights while being economical to operate. We make the GB series affordable and dependable by utilizing many common components.

This is an under-counter beverage bottle crusher machine. It is mainly suitable for bars, outdoor bars, restaurants, cruise ships, resorts, hotels and casinos. To reduce noise, this glass bottle crusher comes with a foam insulated cabinet. It has a stainless steel body. The GlassHopper crushes bottles up to 750 ml and reduces volume up to 80%. This machine has some modern features like a bin full indicator and it automatically shuts off when it reaches 42 lbs.

With a crushing capacity of 600 glass bottles per hour, the two-breaker bar model is great for use at locations like municipalities, bars, restaurants, conventions and recycling centers. The six-breaker bar model is best utilized in laboratories or testing facilities for crushing glass vials, beakers, ampules, amber glass, flasks, pipettes and tubes. This is an economical solution for managing glass waste. It can also crush gallon size jugs or bottles depending on the design.

This is a multipurpose machine that not only crushes glass waste but it also crushes aluminum and steel cans. This glass crusher is ideal for beverage distributors, bottlers / brewers, micro brewers, recycling plants, hotels, resorts, universities and restaurants. It has rated capacities up to 10,000 12 oz. cans per hour, up to 25 1-gallon cans per minute and over 2 tons of glass per hour. Despite the high output, it crushes cans or glass thoroughly and efficiently. Safety engineered throughout. The large, crushing chamber eliminates feed problems and assures a high volume output.

This glass crusher comes with a unique feature. A magnetic head pulleys! It automatically separates steel cans form aluminum cans being processed. It crushes and flattens the cans and crushes the glass into variable cullet. This glass crusher is ideal for beverage distributors, bottlers / brewers, micro brewers, recycling centers, and municipalities. The model 170 can handle 10,000 cans and 3 tons of the glass in one hour.

This is a high-volume glass and can crusher ideally suitable for waste recycling facilities, manufacturers, breweries, and bottlers. This glass crusher machine is easy to operate and requires minimum maintenance. Rated capacities: up to 2,000 lbs. of aluminum cans per hour, 4,000 lbs. of steel cans per hour and 4 tons of glass per hour, Overload compression springs to prevent jamming, Safety engineered throughout, Will crush cans and glass up to and including 5 gallon jugs.

The glass pulverizer is used to convert glass waste into gravel or sand without sharp edges. The internal trommel screen reduces glass to -1/8’ and -3/8’ sizes. It can process up to 1000 lbs. in one hour. This machine automatically separates other waste like plastic, corks and labels into a trash bin. You can move it easily with its 5’ casters. Pulverized glass is used in the making of concrete, golf courses, aquatics, as municipal fill, sandbags, landscaping and construction.

This model comes with a 10” wide feeding conveyor. It’s an economical option for medium size glass recycling facilities. The machine is best suited for islands, resorts, remote locations, municipalities and recycling facilities. The GP-1500C automatically separates labels and other trash from the glass.