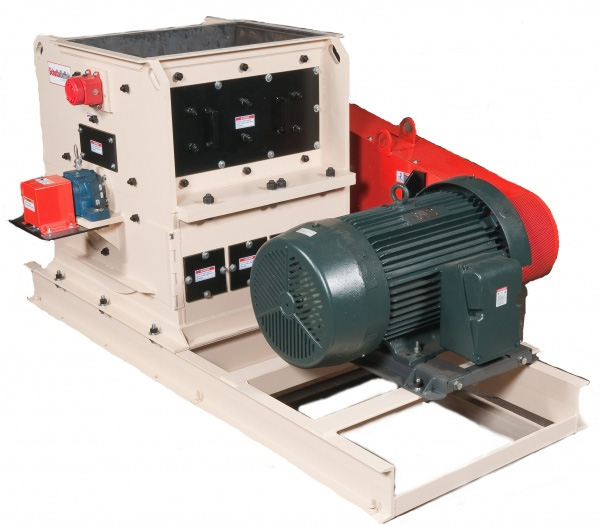

What is a Hammer Mill?

A hammer mill is a machine used to shred or crush materials into smaller pieces. The basic design of a hammer mill involves a rotating shaft to which free-swinging hammers are attached. This assembly is enclosed by a drum which holds the material to be pulverized. A self-tipping hopper, conveyor, or open top hopper feeds the source material into the drum. The hammers gradually break up the material until it is small enough to pass through a screen with openings corresponding to the desired particle size. The material is then discharge via air convey, gaylord/self-tipping hopper, or conveyor.

A hammer mill is a machine used to shred or crush materials into smaller pieces. The basic design of a hammer mill involves a rotating shaft to which free-swinging hammers are attached. This assembly is enclosed by a drum which holds the material to be pulverized. A self-tipping hopper, conveyor, or open top hopper feeds the source material into the drum. The hammers gradually break up the material until it is small enough to pass through a screen with openings corresponding to the desired particle size. The material is then discharge via air convey, gaylord/self-tipping hopper, or conveyor.

Applications: Hammer mills are used for many industrial, research, agricultural and recycling applications. Farm grain machines, sawmills, plastic grain milling, shredding paper, automobile shredding machine, are some of the excellent examples of hammer mills. A hammer mill can be small enough to sit on a countertop and run-on household current, or large enough to shred entire cars.

In the farming section a hammer mill is employed to pulverize grain for livestock feed. These machines have the advantage of being able to process many types of materials as well as producing particles of many sizes by simply changing the output screen. Particles produced this way will be very uniform and tend to have a spherical shape.

In the food processing industries, the hammer mills are used to grind several types of legumes. They are used to grind soya, nutshells, groundnuts, and diverse types of beans. The hammer mills with low hammer blows are used to remove hard nutshells.

In the pharmaceutical and chemical industries, diverse types of hammer mills are used for powder making. All required ingredients are crushed in hammer mills, and an intermediate grade of powder is obtained. Precise grain size can be obtained in using the hammer mills. Also mainly in pharmaceutical industries, the hammer mills are used for micronization (size reduction). The medicinal grains are required to fit inside the capsule packaging in precise quantity. Therefore, the grains are micronized using the hammer mills before packaging to reduce size.

In chemical, food and pharmaceutical industries, the hammer mills are also used for formulation and quick dissolution. During the dissolution, the small-sized particles dissolve faster. Therefore, hammer mills are used for fast formulation.

In heavy industrial section, uses for hammer mills include many types of recycling operations, including glass crushing and pulverizing, producing pulp for paper production, bio-fuel production, and stone crushing. Grinding grain for ethanol production or pulverizing fruit in juice production are other uses for a hammer mill. A sawmill may employ a hammer mill for the purpose of grinding scrap into mulch or material for manufacturing wood pellet fuel.

In industries like waste management, recycling, and size reduction, hammer mills are used for grinding scrap metal into small pieces for separation and processing. Large hammer mills can grind up entire cars at one time, pulverizing them into fist sized pieces, and can process many tons of scrap metal each day. Other types of hammer mills are used to reclaim recycled asphalt, electronic components, or old tires.

Small hammer mills are sometimes used in laboratories for grinding the materials for growing media or experiments. Other small hammer mills can be employed in grinding foods or spices, and food waste is often processed by these machines. The common garbage disposal is a variation of a hammer mill with a disk with fixed teeth and grinding surfaces instead of free-swinging hammers.

Learn More About Hammer Mills